About us

We have been in business for 15+years and our products/solutions are currently deployed in 35+ countries.

Our global customer base includes large corporations as well as deep tech startups. Our customized solutions are tailor made to meet the specific requirements of your business.

As a team, we are passionate about leaving a better planet for future generations. We want to leverage technology to build solutions that can help mitigate ongoing environmental crisis

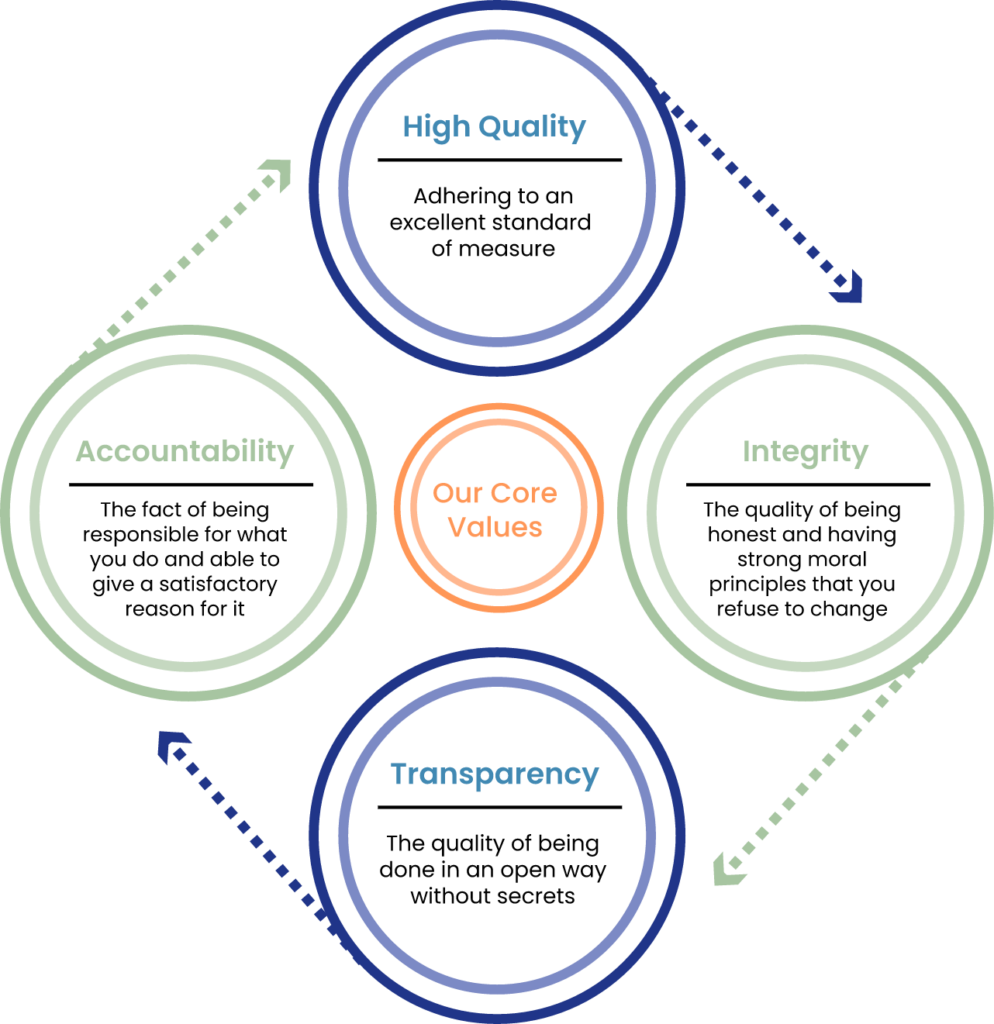

Denvik’s Values

We will achieve the above objectives by promoting an inclusive culture and workplace environment of mutual respect, accountability, high quality, business integrity and transparency. A core guiding principle for the company is to be socially responsible in all our actions.

Quality policy

At Denvik, we believe in a Quality First approach in everything we do. This is an integral part of our DNA and company culture.

Our talented team is always looking to deliver high quality products and services for our customers that meet all regulatory requirements.

Denvik’s approach

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam,